The authors developed a coprocessed adjuvant consisting of microcrystalline cellulose, dibasic calcium phosphate dihydrate, and croscarmellose sodium. The properties of each component were evaluated and tablets of nimesulide were prepared to evaluate the functionalities of the coprocessed diluent. It was determined that the developed adjuvant exhibited satisfactory tableting characteristics.

**********

Direct compression is widely used in tableting because it requires fewer processing steps, is simpler to validate, and improves drug stability when compared with the wet granulation method (1). Direct compression also eliminates exposure to heat and moisture during processing and is a more economical process. However, the majority of active pharmaceutical ingredients exhibit poor compressibility. Therefore, the addition of directly compressible adjuvants is mandatory in such cases.

A directly compressible filler-binder must exhibit good flowability and compactibility. Good flowability is necessary to ensure rapid and uniform die filling, whereas high compactibility is necessary to produce tablets having sufficient mechanical strength (2). No single diluent is likely to possess all the ideal characteristics. For this reason, the current trend in industry is to use multifunctional coprocessed adjuvants.

A survey conducted by Shangraw and Dermarest revealed that the most commonly used fillers for tablets and capsules are lactose, microcrystalline cellulose (MCC), starch, and dibasic calcium phosphate dihydrate (DCP) (3). MCC is well known as a tablet diluent, binder, and disintegrant. It is a ductile material that shows plastic deformation on compaction, which helps produce stronger tablets. However, MCC also is sensitive to hydrophobic lubricants and shows poor flowability, and therefore must be modified into large particles or agglomerates to improve its flow characteristics.

DCP has a high fragmentation propensity and therefore is insensitive to hydrophobic lubricants. It is also heat stable and has good flow properties (4). Other advantages of DCP are its low hygroscopicity and low cost. Sangekar et al. evaluated the performance of eight directly compressible excipients. Based on the results of hardness, change in disintegration time, moisture uptake, and change in volume, DCP was reported as the preferred directly compressible adjuvant (5). DCP is best used in direct compression when combined with MCC (6).

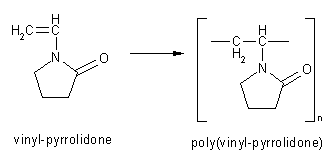

Several coprocessed filler-binders are commercially available, including Cellactose ([alpha]-lactose monohydrate and powdered cellulose 75:25), Microcelac ([alpha]-lactose monohydrate and powdered cellulose 75:25), Ludipress (93% [alpha]-lactose monohydrate, 3.5% polyvinylpyrrolidone, and 3.5% crospovidone), and Pharmatose DCL 40 (95% anhydrous [beta]-lactose and 5% lactitol) (7). The main objective of developing a coprocessed adjuvant is to obtain the advantages of each component in a single adjuvant. A combination of MCC, DCP, and croscarmellose sodium has not been fully explored either by industry or by researchers as a directly compressible multifunctional diluent. Therefore, in this investigation a coprocessed adjuvant consisting of the two diluents and croscarmellose sodium was developed.

Nearly all excipients for direct compression are manufactured by granulation, agglomeration, cocrystallization, or spray drying. Spray drying has been used commercially to manufacture excipients with good flowability and compressibility, but spray-dried products exhibit poor reworkability. Crystallization requires critical control of processing parameters. The method of wet granulation was adopted in this study because of its simplicity. The efficacy of the adjuvant was assessed by developing quick-disintegrating tablets of nimesulide.

Materials and methods

Materials. Nimesulide (100#) was received as a gift from Redson Pharmaceuticals Ltd. (Ahmedabad, India). MCC IP (MCC, 100#), starch, polyvinylpyrrolidone (PVP K30), hydroxypropyl methylcellulose (HPMC K15), and polyethylene glycol (PEG 4000) were received as gifts from Zydus Cadila Health Care Ltd.(Ahmedabad). DCP IP (DCP, 100#) was provided free of charge by Enar Chemie Pvt. Ltd. (Navsari, India). Croscarmellose sodium, sodium starch glycolate, and crospovidone were received as gift samples from Maruti Chemicals (Ahmedabad). Cab-O-Sil M5 was a gift from Cabot Sanmar Ltd. (Madras, India). Magnesium stearate (Vikas Pharma, Ahmedabad) and talc (JC Chemicals, Ahmedabad) were of IP grade.

Methods, Evaluation of binders. The premix of MCC and DCP (70:30, 50 g) was sieved and then remixed. The blend was granulated using starch paste (Batch [A.sub.1], 10% w/v), PEG 4000 (Batch [A.sub.2], 26% w/w PEG 4000), PVP (Batch [A.sub.3, 10% w/v PVP), or HPMC (Batch [A.sub.4], 0.5% w/v HPMC) as a binder. A melt granulation technique was adopted for PEG 4000 and a wet-granulation technique was used for the rest of the binders. The liquid binder was mixed with the powder blend for 3 min and then the damp mass was warmed at 60 [degrees]C for 15-30 min in a hot-air oven to facilitate granulation. The wet coherent mass was then passed through a 44 mesh. The granules were dried at 60 [degrees]C for 90 min in a hot-air oven. The dried granules were again passed through a 44 screen. Fines were removed by shifting the granules on a 120 mesh. The granules were evaluated for angle of repose and Carr's index. Talc (2%) and magnesium stearate (1%) were mixed with the granules, and tablets with an average weight of 220 mg were prepared on a single-punch tablet machine (Cadmach Machinery Ltd., Ahmedabad). Tablets were evaluated for crushing strength and disintegration and the results are shown in Table I.

Angle of repose. Angle of repose was measured using the fixed-funnel method with a reposograph (model 640, Enar Foundation Research Center, Navsari) (8). Per the manufacturer's instruction, the samples were graded as excellent, good, fair, or meager if the angle of repose was found to be in the range of 30-32[degrees], 32-35[degrees], 35-37[degrees], or 37-45[degrees], respectively.

Bulk density and tapped density. The granules were filled in a 100-mL capacity measuring cylinder up to the 75-mL mark. Bulk density is the quotient of weight to the volume of a sample. Tapped density is the quotient of weight of a sample to its volume after tapping the measuring cylinder 500 times at a height of ~1.5 in.

Carr's index. The percentage compressibility (Carr's index) was calculated as 100 times the ratio of the difference between tapped density and bulk density to the tapped density (9).

Crashing strength. The crushing strength of the tablets was determined after 24 h of compression (time for stress relaxation) using a Monsanto hardness tester (Shital Scientific Industries, Mumbai, India).

Friability. Friability was evaluated from percentage weight loss of 20 tablets tumbled in a friabilator (model EF2, Electrolab, Mumbai) at 25 rpm for 4 min. The tablets then were dedusted, and the loss in weight caused by fracture or abrasion was recorded as percentage weight loss.

Disintegration time. The time required for disintegration of six tablets placed in the tubes of a disintegration test apparatus (model ED2, Electrolab, Mumbai) was measured at 37 [+ or -] 2 [degrees]C using 900 mL distilled water (10).

Evaluation of superdisintegrants. Croscarmellose sodium (CCS), sodium starch glycolate (SSG) and crospovidone (CRP) were tried as superdisintegrants at a level of 4%. Granules were prepared using starch paste (10% w/v) and were compressed on a single-punch tablet machine. Each tablet was evaluated for disintegration in a petri dish (diameter = 5.5 cm). A tablet was placed carefully in the center of a petri dish containing 20 mL of water. The tablet was allowed to wet for 30 s and then the petri dish was subjected to 10 oscillations of one inch each. Particle-size measurements were performed using a microscopic method after decanting the clear liquid. The results are shown in Figure 1.

Preparation of physical blend of MCC and colloidal silicon dioxide. A physical blend of 97% MCC and 3% colloidal silicon dioxide was prepared by blending them in a glass mortar for 30 min. The silica-treated MCC (35 g), DCP (15 g), and croscarmellose sodium (2 g) were blended subsequently. The granules of 44/120 # were prepared using starch paste (10% w/v) as a binder and then were evaluated for angle of repose and Carr's index. Tablets containing silica-treated MCC and untreated MCC were separately prepared and compared (see Table II, Batch B).

Lubricant sensitivity test. The effect of magnesium stearate on the crushing strength and the disintegration of tablets containing treated MCC as well as untreated MCC were studied (batches [C.sub.1]-[C.sub.4]). Magnesium stearate (1%) was mixed with the granules for 2 min in a glass jar. The granules ready for compression were compressed into tablets and the tablets were evaluated for crushing strength and disintegration. Table lII shows the results of the lubricant sensitivity test.

Effect of blending time. DCP (15 g) was mixed with a part of starch paste (4.8 g) in a mortar for 15 min. Then silica-treated MCC (35 g), the remaining part of starch paste (1.6 g), and croscarmellose sodium (4%) were added and the granules (44/120 #) were prepared. Magnesium stearate (1%) was added and the granules (Batch D) were subjected to preliminary tests. The results were compared with Batch C4, for which the blending time was only 3 min (see Table IV). Batch D was evaluated for dilution potential and moisture uptake.

Dilution potential. Nimesulide was used as a model of a poorly compressible drug. The tablets containing various drug--diluent ratios (Batch D) were prepared (see Table V). The nimesulide tablets were evaluated for crushing strength, friability, and disintegration time.

Moisture uptake. The granules of Batch D (2 g) were spread in a petri dish with a diameter of 5.5 cm and the dish was placed in a sealed dessicator (at 75% relative humidity (RH) and 40 [degrees]C). The percentage increase in weight was noted after two days.

Preparation of nimesulide tablets. The tablets containing nimesulide (50 mg) and granules of Batch D (163.4 mg), talc (4.4 mg), and magnesium stearate (2.2 mg) were prepared on a single-punch tablet machine fitted with 9-mm flat-faced punches. The average weight of the tablets was 220 mg. The tablets were evaluated for crushing strength, friability, disintegration time, and in vitro drug dissolution.

In vitro dissolution study. An in vitro dissolution study of the nimesulide tablets was carried out using a phosphate buffer (pH 7.4, 900 mL, 37 [+ or -] 0.5 [degrees]C) and a USP 23 basket apparatus (50 rpm). Samples (5 mL) were withdrawn at predetermined time intervals, filtered through a 0.45-[micro]m filter and assayed at 394 nm using a UV--vis spectrophotometer (Hitachi U2000, Tokyo, Japan) to determine the percentage of drug released. The same volume (5 mL) of fresh dissolution medium (at 37 [+ or -] 0.5 [degrees]C) was replenished immediately after the sample was withdrawn.

Results and discussion

The use of a one-body adjuvant is justified if it results in potentiation of the functionalities of the components compared with a physical blend of individual components. The synergistic effect may result in improved flow, compressibility, or tablet quality.

Flow of the sample is ranked as "good" if the value of Carr's index falls within 5-15% (9). The samples of MCC, DCP, and a physical blend consisting of MCC and DCP in a 70:30 ratio exhibited poor flow (angle of repose > 37 [degrees] and Carr's index > 17%). These poorly flowing adjuvants are expected to yield tablets of varying weight (11). The use of granulation leads to improved flow, improved compressibility, better homogeneity, and reduced dust formation during manufacturing (12). For this reason, the wet-granulation method was used to develop a directly compressible adjuvant.

Bolhuis et al. reported that the compaction behavior of the two diluents is different (2,7). MCC undergoes plastic deformation on compaction, but DCP shows a high fragmentation propensity. Bolhuis et al. further concluded that with regard to compaction neither purely brittle (e.g., DCP) nor purely plastic (e.g., MCC) properties are desirable. The deteriorating effect of magnesium stearate on the crushing strength of tablets is more pronounced when the material undergoes plastic deformation (e.g., MCC), however almost no effect is noticed if the diluent exhibits a high fragmentation propensity (e.g., DCP). Hwang et al. reported that the friability of DCP tablets increased substantially on storage whereas that of MCC tablets increased slightly (13). Jivraj et al. reported that good compression characteristics can be obtained with 10-33% DCP and 66-90% MCC (6). Villafuerte et al. stated that tablets containing MCC and DCP in a ratio of 68:32 exhibited the fastest disintegration time (14). These observations justify the development of co-processed agglomerates containing MCC and DCP. Therefore, in this investigation, MCC and DCP were used in a ratio of 70:30.

Evaluation of binder. The steps of premixing, sieving, and remixing were carried out in succession to obtain good mixing properties (15). Among all the binders tried, starch paste (10% w/v) exhibited the lowest Carr's index (6%), angle of repose (31%), and disintegration time (12 s). Considering the results (see Table I), starch paste (10% w/v) was selected as a binder for further studies. The higher disintegration time seen in PEG 4000 can be attributed to poor water uptake by the tablets. It has been reported that the use of PEGs prolongs disintegration if present in concentrations > 5% w/w (16).

Evaluation of superdisintegrants. When starch paste was used as a binder, the tablets disintegrated within 15 s but the disintegrated particles were of large size. One of the requirements of a mouth-dissolving or dispersible tablet is that the tablet must yield fine particles on disintegration. Figure 1 shows that 4% intragranular croscarmellose sodium exhibited the lowest average particle size after disintegration. Thus, one may conclude that the manner and method by which the disintegrant is added should be carefully selected to attain fast tablet disintegration and the formation of small particles on disintegration. Considering the results, further trials were carried out with 4% w/w intragranular croscarmellose sodium.

Evaluation of physical blend of MCC and colloidal silicon dioxide. Various studies claim that the loss of the compactibility of MCC when using wet granulation is less for tablets containing silicified MCC (SMCC) than for tablets containing untreated MCC (7,17-19). In this investigation, a blend of MCC (97%) and colloidal silicone dioxide (3%) was tested to minimize the deleterious effect on the compactibility of MCC. Table II shows that the crushing strength of the tablets containing silica-treated MCC was quite high (8.5 kg) compared to the tablets containing untreated MCC (5 kg). Other parameters such as angle of repose, Carr's index, and disintegration time remained almost unchanged.

Lubricant sensitivity test. Magnesium stearate affects the crushing strength and the disintegration time of tablets containing a diluent that undergoes plastic deformation (e.g., MCC) on compaction, but fragmenting materials (e.g., DCP) are less lubricant sensitive (2,7). A decrease in the crushing strength of the tablet after inclusion of a lubricant indicates lubricant sensitivity. SMCC is insensitive to magnesium stearate because colloidal silica coats magnesium stearate particles and thus prevents the formation of a lubricant film on the MCC particles (1). The results shown in Table III reveal that the coprocessed diluent containing silica-treated MCC and DCP is lubricant insensitive.

Effect of blending time. The starch paste was added in two steps in the wet granulation process to minimize the detrimental effect of water on the compactibility of MCC. The crushing strength of tablets depends on the blending time of the binders with a powder blend (20). These results have been observed in this study. When the starch paste was mixed for 15 min rather than only 3 min, the crushing strength of the tablets was increased by 4 kg (see Table IV). Tablets of the same crushing strength (5 kg) were separately prepared and evaluated for disintegration time. The tablets of Batches [C.sub.4] and D disintegrated in less than 20 s.

Dilution potential. Table V depicts the results of the dilution potential study of Batch D for the five ratios. The minimum acceptable limits for crushing strength ( >5 kg), friability ( < 0.8%), and disintegration time ( < 1 min) were selected as criteria for the selection of batches. Batches D-[D.sub.3] met the selection criteria. One can conclude that as much as 30% of nimesulide can be accommodated in the coprocessed diluent.

Moisture uptake. Water absorption can influence the chemical stability of the drug and the physical properties of the granules or tablets. The chemical degradation of the drug is enhanced because the drug dissolves in the absorbed water layer that surrounds individual particles. Physical properties such as binding, flow, and compaction change as the water content of the adjuvant changes. The granules of batch D absorbed 2% w/w of moisture when stored at 75% RH and 40 [degrees]C for 2 days. The results revealed that Batch D was reasonably moisture insensitive.

Evaluation of nimesulide tablets. An ideal tablet should exhibit adequate mechanical strength and fast disintegration. The crushing strength, friability, and disintegration time for tablets prepared using granules of Batch D were 5.5 kg, 0.7%, and 40 s, respectively. The results are within the limits specified for the dilution potential study.

In vitro dissolution. Fifty-seven percent of the nimesulide was released in 4 h from the tablets because of the low solubility (0.1 mg/mL) of nimesulide in phosphate buffer (21). Nimesulide powder (50 mg) was filled in hard gelatin capsules for comparison. The capsules showed 51% drug release after 4 h. Figure 2 shows the comparative dissolution profiles of nimesulide from tablets and the reference capsules. The two dissolution profiles are similar at the 5% level because the similarity factor, [f.sub.2], was calculated as 68 (22).

[FIGURE 2 OMITTED]

Conclusion

A coprocessed multifunctional diluent consisting of MCC, DCP, and croscarmellose sodium was developed in this investigation. The blending of MCC with colloidal silicon dioxide before wet granulation led to the formation of stronger tablets. The coprocessed adjuvant did not pick up a significant amount of moisture when stored at 75% RH for 2 days. As much as 30% of nimesulide can be incorporated in the optimized batch for successful production of tablets by direct compression. The disintegration time of the formulated tablets was less than 2 min and therefore this formulation may be used for mouth-dissolving or dispersible tablets.

Acknowledgment

We are thankful to the various organizations listed in the materials section for providing gift samples. Dr. M.C. Gohel and Dr. L.D. Patel are thankful to All India Council for Technical Education for providing financial assistance.

References

(1.) G.K. Bolhuis, and Z.T. Chowhan, "Materials for Direct Compaction" in Pharmaceutical Powder Compaction Technology, G. Alderborn and C. Nystrom, Eds. (Marcel Dekker, Inc., New York, 1996), pp. 419-500.

(2.) G.K. Bolhuis and K. Van der Voort Maarschalk, "Improving Properties of Materials for Direct Compaction Part I," Pharm. Technol. Eur. 10 (9), 30-33 (1998).

(3.) R.F. Shangraw and D.A. Demarest Jr., "A Survey of Current Industrial Practices in the Formulation and Manufacture of Tablets and Capsules," Pharm. Technol. 17 (1), 32-38 (1993).

(4.) N.V. Mulye and S.J. Turco, "Use of Dicalcium Phosphate Dihydrate is for Sustained Release of Highly Water Soluble Drugs," Drug. Dev. Ind. Pharm. 20 (17), 2621-2632 (1994).

(5.) S.A. Sangekar, M. Sarli, and P.R. Seth, "Effect of Moisture on Physical Characteristics of Tablets Prepared from Direct Compression Excipients," J. Pharm. Sci. 61 (6), 939-944 (1972).

(6.) M. Jivraj, L. G. Martini, and C.M. Thomson, "An Overview of the Different Excipients Useful for the Direct Compression of Tablets," Pharm. Sci. Technol. Today 3 (2), 58-63 (2000).

(7.) G.K. Bolhuis and K. Van der Voort Maarschalk, "Improving Properties of Materials for Direct Compaction Part II," Pharm. Technol. Eur., 10 (10), 28 31 (1998).

(8.) A. McKenna and D.E McCafferty, "Effect of Particle Size on the Compaction Mechanism and Tensile Strength of Tablets," J. Pharm. Pharmacol. 34 (6), 347-351 (1982).

(9.) R.L. Carr, "Evaluating Flow Properties of Solids," Chem. Eng. 72, 163-168 (1965).

(10.) USP 24-NF 19 (United States Pharmacopoeial Convention. Inc., Rockville, MD, 2000), pp. 1941-1942.

(11.) J.N. Staniforth, B.E. Sherwood, and E.A. Hunter, "Pharmaceutical Excipient having Improved Compressibility," US Patent 5,866,166 (1999).

(12.) F. Heinze, "Starch--the Natural Excipient Choice", Manuf. Chem. 73 (8), 40-42, (2002).

(13.) Ruey-ching Hwang et al., "Tablet Relaxation and Physicomechanical Stability of Lactose, Microcrystalline Cellulose, and Dibasic Calcium Phosphate," Pharm. Technol. 25 (11), 54-80 (2001).

(14.) L. Villafuerte-Robles and J. Lopez-Solos, "Effect of Disintegration with Different Hygroscopicity on Dissolution of Norfloxacin/Pharmatose DCL 11 Tablets," Int. L Pharm. 216, 127-135 (2001).

(15.) R. Eyjolfsson," Mixing of Pharmaceutical Powders," Pharmazie 56(7), 590-591 (2001).

(16.) J.C. Price," Polyethylene Glycol," in Handbook of Pharmaceutical Excipients, A. Wade and P. J. Weller, Eds. (American Pharmaceutical Association/The Pharmaceutical Press, Washington DC/London, Second Edition, 1994), pp. 355-361.

(17.) N.A. Armstrong et al., "Cellactose as a Tablet Diluent," Manuf. Chem. 67 (10), 25-26 (1996).

(18.) N.A. Armstrong, "Criteria for Assessing Direct Compressible Diluents," Manuf. Chem. 57 (12), 29 31 (1986).

(19.) E.J. Mendell, "Direct Compression Method of Producing Solid Dosage Forms," Manuf. Chem. Aero. News 43 (3), 47-49 (1972).

(20.) T. Suzuki et al., "The Change in Characteristics of Microcrystalline Cellulose during Wet Granulation using High Shear Mixer," J. Pharm. Pharmacol. 53 (5), 609-616 (2001).

(21.) N. Seedher and J. Kaur, "Solubilization of Nimesulide: Use of Cosolvents," Ind. J. Pharm. Sci., 65 (1), 58-61 (2003).

(22.) V.P. Shah et al., "In Vitro Dissolution Profile Comparison--Statistics and Analysis of the Similarity Factor [f.sub.2]," Pharm. Res. 15 (6), 889-896 (1998).

Mukesh C. Gohel is a professor and principal; Laxman D. Patel is a senior lecturer and postgraduate guide; and Shital H. Bariya, Rikita K. Dave, and Nehal H. Bariya are postgraduate students, at the Department of Pharmaceutics and Pharmaceutical Technology, L.M. College of Pharmacy, Navarangpura, Ahmedabad-380 009, INDIA, tel. +91 79 6302746, fax +91 79 6304865, mukeshgohel@hotmail.com.

Mukesh C. Gohel, To whom all correspondence should be addressed

COPYRIGHT 2003 Advanstar Communications, Inc.

COPYRIGHT 2004 Gale Group