JAMES A. GESSAMAN,(1,3) ROY D. NAGLE,(2) AND JUSTIN D. CONGDON(2)

ABSTRACT.-The mean absolute percent error of predicting the fat mass of 40 Rock Doves (Columba livia) by the cyclopropane absorption method was 11%. A sensitivity analysis of some of the 15 variables used in computing fat mass by the cyclopropane absorption method showed that: (1) cloacal temperature was a good measure of body-fat temperature, (2) the lipid solubility coefficient of cyclopropane reported for rats was appropriate for pigeons, (3) minimum error occurred with an animal density of 1.08, (4) error was relatively insensitive to a range of reasonable estimates of body water, and (5) the most accurate method of measuring chamber volume was unclear. We list advantages and disadvantages of this user-unfriendly method and provide recommendations for future users. This method does not require a calibration based on fat extracted from dead birds; the accuracy and precision of a system assembled to measure the fat mass of live birds can be evaluated with olive oil standards. The accuracy of estimating fat mass of a living bird seems to be dictated, in large part, by the analytical equipment and procedures used rather than by the bird. Received 14 April 1997, accepted 21 July 1997.

THE LACK OF AN ACCURATE nondestructive or noninvasive technique for determining whole body-fat storage is one of the greatest hindrances to studies of avian ecological energetics. Fat, which has an energy content of about 2.5 times that of protein or carbohydrate per unit dry mass and about 8 times per unit wet mass, is the main energy store in birds (Pond 1981, Blem 1990). Mass of body fat (FM) is one quantitative measure of a bird's preparedness for successfully completing an energy-demanding activity such as migration or egg laying and surviving such energy-demanding periods as: (1) prolonged starvation (Cherel et al. 1987), (2) summit (peak) rates of energy metabolism during a severe winter period, or (3) an unseasonably cold storm during a nonwinter period (see Gessaman and Worthen 1982, Elkins 1993).

The most accurate method of determining FM is extraction with a solvent such as petroleum ether, but the technique requires killing the animal. Because it is undesirable to kill subject animals, researchers have evaluated several nonlethal (and typically noninvasive) methods of estimating body fat of birds. These methods include total body electrical conductivity (TOBEC; Skagen et al. 1993), fat scoring (Krementz and Pendleton 1990, Rogers 1991), and morphological variables such as body mass and wing length (see Blem 1990). Another method, which is nonlethal and noninvasive, uses the absorption of cyclopropane gas into an animal's body to estimate FM. The cyclopropane method has been validated twice on small animals: 10 laboratory rats (Lesser et al. 1952) and 6 pond turtles (Trachemys scripta; Henen 1991), but not on birds. The percentage error in the estimate of the rats' FM was 5.6 (x(bar) = 13.2% of body mass, range 8.1 to 18.9%), and the estimate of the pond turtles' FM was only 10%, despite the low FMs (0.7 to 3.5% of body mass) in Henen's (1991) study. Because these errors are smaller than those reported in most studies that have evaluated other nonlethal methods of estimating body fat in birds, we questioned whether this method would be as accurate for birds. Our study is the first evaluation of the cyclopropane absorption method for measuring avian body fat.

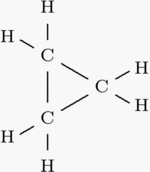

Cyclopropane gas (CYP) is about 24 times more soluble in fat than in lean mass (Blumberg et al. 1952, Lesser et al. 1952). Lean mass is the portion of the body that would remain when all nonpolar (neutral) lipids, (i.e. triglycerides) are chemically extracted with a nonpolar lipid solvent (e.g. petroleum ether). In contrast, fat-free mass is the portion of the body that would remain when all lipids (polar and nonpolar) are chemically extracted (e.g. with a chloroform/ methanol mixture). The concentration of cyclopropane gas in an airtight chamber containing an animal, 1.5% cyclopropane, and 98.5% oxygen decreases as the cyclopropane is breathed in and dissolves into the FM and lean mass of the animal. From measures of the initial and final equilibrium concentrations of CYP in the animal chamber, the animal's FM is calculated in three steps: (1) subtracting moles of CYP remaining in the animal chamber at equilibrium from the moles of CYP injected into the chamber equals the moles of CYP absorbed by the animal (see Appendix 1); (2) subtracting an estimate of the moles of CYP dissolved in the lean mass (equation 12) from the result of step 1 equals the moles of CYP absorbed by the animal's FM (numerator of equation 14); and (3) dividing the results from step 2 by the moles of CYP dissolved in each g of fat (equation 13) equals the FM (g).

METHODS

Study animals.-Nineteen small to medium-sized Rock Doves (Columba livia; a mix of tippler, Serbian, Catalonian, and French cumulet breeds [hereafter "pigeons"]; body mass 252 to 340 g, fat mass 16 to 55 g, and 5 to 18% fat mass) and 21 homing pigeons (body mass 378 to 501 g, fat mass 43 to 94 g, and 10 to 22% fat mass) were used in this study. These birds were given water and food ad libitum for several weeks prior to the experimental treatments.

Apparatus and experimental procedure.-A pigeon was positioned head first into an aluminum cylinder (which held its wings against the body) until its bill touched the wire mesh covering the cylinder end. The cylinder was then placed concentrically inside the base of a horizontally mounted 3.5- or 4.5-L glass reaction kettle (Ace Glass Incorporated, Vineland, New Jersey; hereafter called "the chamber"; Fig. 1). One pouch, made from stapled aluminum screen and containing 60 g of soda lime, and another containing 120 to 190 g of Drierite, were placed between the chamber wall and the aluminum cylinder to absorb CO2 and H20 respectively. We placed an egg-shaped magnetic stir bar on the ventral curved surface near the center of the chamber to mix chamber gases. The chamber rested on top of a magnetic stir plate.

The glass lid of the chamber had three ports, two of which housed two-way Teflon stopcocks and one that contained an adapter to hold a manometer and a copper-constantan thermocouple wire. Chamber gas samples (20 muL) were obtained from one stopcock for cyclopropane analysis, and 100% oxygen or room air was injected into the chamber through the other stopcock to restore lowered chamber pressure (created by the animal's consumption of oxygen and the chemical absorption of its CO^ sub2^ in the chamber) to atmospheric pressure. A U-shaped glass manometer, which contained glycerol and measured chamber pressure, was attached with Teflon tape to the glass adapter, and a thermocouple wire, which measured chamber-gas temperature, entered the side arm of the adapter and extended 2 cm into the chamber. The manometer detected decreases in chamber pressure as the animal consumed oxygen. Material surfaces within the chamber included glass, aluminum, Teflon, and glycerol. Cyclopropane is not absorbed by these materials but is soluble in commonly used laboratory materials such as rubber, stopcock grease, and plastic.

A Teflon gasket, smeared with a thin layer of glycerol, was positioned between the lid and base of the chamber and held firmly in place with a clamp that applied pressure completely around the flange of the lid and base. After the lid was tightened, we temporarily removed the adapter containing the manometer from the lid, and flushed 100% O^ sub2^ into the chamber through this port for about 2 to 3 min. The adapter was replaced, both stopcocks were closed, and the magnetic stirrer started. Fifty mL of air was withdrawn from the sealed chamber and replaced with 50 mL of cyclopropane withdrawn from a gas cylinder. Before injection, the syringe needle was purged to atmospheric pressure by placing it under water until bubbling of cyclopropane from the syringe had stopped.

After two and one-half hours, 20-wL samples of chamber gas were removed every 10 to 15 min and analyzed with a Hewlett Packard 5890A Gas Chromatograph (FID, 1.8 m glass column packed with 0.19% picric acid in Carbopack [Supelco Inc., Bellefonte, Pennsylvania], 100 degC isothermal). Sampling continued until the SD of the mean of three samples was less than 0.75%. Cyclopropane concentration was calibrated using external standards that were made by injecting 10 to 18 mL cyclopropane into 1L volumetric flasks. The relationship of peak area versus cyclopropane concentration was completely linear throughout the range of cyclopropane concentration used in the experiments. At the end of each experiment, we measured the mass and body temperature of the pigeon within 30 s of removal from the chamber, after which the pigeon was euthanized with N^ sub2^ and frozen.

Lipid analysis.-Carcasses were partially thawed, most feathers were removed with scissors, and then weighed. Cuts were made in the head, wing muscles, abdomen, and legs, and carcasses were stapled in a packet of aluminum wire screen and refrozen. Carcasses were freeze-dried for 48 to 72 h and then airdried at 60 degC in a convection oven to constant mass. We removed dried carcasses from the screen packet, weighed them, and then ground them to a uniform consistency with a Knifetec Tissue Homogenizer (Perstorp Analytical, Silver Spring, Maryland). Subsamples of the ground birds were placed in preweighed cellulose thimbles, weighed, and extracted with Soxtec HT2 and HT6 extraction units (Perstorp Analytical, Silver Spring, Maryland). Petroleum ether, used as the extraction solvent, removes only nonpolar lipids and therefore is recommended for body composition studies (Dobush et al. 1985). Empty thimbles, and those containing pre- and post-extraction samples, were weighed inside a dry box maintained at less than 0.5% relative humidity. We calculated percent fat in each subsample as the difference between the mass of the sample before and after extraction divided by the mass of the sample before extraction. Subsamples from each bird were extracted until the standard deviation of the mean of two samples was less than 0.75%. Total nonpolar FM for each bird was calculated as the product of percent nonpolar fat and total dry mass.

The equations we used to compute FM from cyclopropane absorption data are shown in Appendix 1. The variables required in these equations and the methods of measuring them are shown in Table 1 and described below.

Volume of animal chamber.-Chamber volume was measured in two ways. First, we weighed the water volume required to completely fill the empty chamber. Water density was corrected for water temperature. Prior to the volume measurement, the water was boiled to remove air bubbles and cooled to room temperature in a sealed container. Second, we calculated the volume of the chamber (V2) from the measured dilution (C2) of cyclopropane after the injection of 50 mL (V^sub 1^) of 100% cyclopropane (C,) injected into the empty chamber.

Volume of pigeon.-The difference between empty chamber volume and volume of the chamber containing one frozen pigeon carcass (463 g) was regarded as the volume of that pigeon (418 mL). Both chamber volumes were measured by cyclopropane dilution. This pigeon's density (1.1 kg/L) was then used to compute the volume of all live pigeons in this study from their body mass.

Volume of other materials in chamber.-The masses and densities (p) of soda lime (NaOH; p = 2.13 g/mL; Chemical Rubber Company 1982), Drierite (anhydrous CaSO^ sub4^; p = 2.96 g/mL; Chemical Rubber Company 1982), aluminum wire screen (p = 2.48 g/mL; Henen 1991), and copper tubing (p = 8.95 g/mL) were used to compute the volumes of these materials. When a small pigeon occupied the chamber, unopened tin cans were added to reduce the effective volume of the chamber because, in theory, smaller effective volumes result in a larger difference between the initial and final mole fractions of cyclopropane in the chamber, thus reducing the error of the FM estimate. We measured the volume of the tin cans and stir bars by water displacement.

Solubility coefficients of cyclopropane.-Blumberg et al. (1952) measured the solubility coefficient (alpha) of cyclopropane in pooled rat fat at 27.5, 34.0, and 37.5 degC. We computed a at pigeon body temperatures (TKB) from 38.8 to 46.6 degC from a linear regression equation derived from the data of Blumberg et al.:

alpha = 4.8209 x 10^ sup-3^ -1.3969 x 10^ sup-5^ (TKB), (1) with eL in moles/g and TKB in degK (r = -0.999). We used the solubility of cyclopropane in lean tissue at 35 degC as reported by Blumberg et al. (1952) to compute cyclopropane absorption in lean mass.

Testing the system.-We tested all three chambers in 30 trials by injecting 50 mL of cyclopropane into each sealed chamber containing a weighed quantity of olive oil ranging from 20 to 80 g. The olive oil was magnetically stirred in a glass dish within the chamber during the two- to three-hour equilibrium period (the chamber sat vertically on the magnetic stir plate). We used the final temperature in the chamber (ranging from 29 to 31 degC) and the solubility coefficients (at) of cyclopropane in olive oil to compute an estimate of the mass of oil. We derived the following functional relationship between the oL of cyclopropane in olive oil and temperature (TKF) from five data points in Blumberg et al. (1952:table 2):

alpha = 5.083 x 10^ sup-3^ - 1.495 x 10^ sup-5^ (TKF), (2)

with alpha in moles/g and TKF in degK, (r = -0.996). We found that the estimated oil mass was consistently less than the actual oil mass. While troubleshooting the potential causes of this error, we discovered that the 10-mL gas syringe used to deliver 50 mL of cyclopropane into the chambers leaked during delivery. A new 50-mL gas syringe, which did not leak, was used in all pigeon trials. We recommend that future users of the cyclopropane method test their system with olive oil before beginning body-fat measurements on animals.

RESULTS

Fifteen input variables are required to compute FM by the cyclopropane absorption method. We obtained two different values for one of those variables ( i.e. chamber volume). Chamber volumes measured by cyclopropane dilution were 0.94 and 1.45% larger than those measured by water volume for two 3.5-L chambers, respectively, and 1.18% larger for the 4.5L chamber (Table 2).

Despite this discrepancy, we determined the most accurate measure of chamber volume by computing the FM of each pigeon using a series of values of chamber volume, which were incremented around water volume and included cyclopropane dilution volume, and then plotting the mean percent error of these computed FM estimates against chamber volume. The errors were smallest for the 3.5-L chambers at chamber volumes that were 1.90% smaller than water volume, and for the 4.5-L chamber at a chamber volume that was 3.85% smaller than water volume. At these chamber volumes, the mean absolute minimum error of estimating FM was 11%, i.e. 11.8% (SD = 9.0, n = 30) and 9.4% (SD = 8.2, n = 10), respectively, in the 3.5L chambers and 4.5-L chamber (Fig. 2). Using chamber volumes estimated by water volume, the mean absolute error of estimating FM in the 3.5-L chambers and 4.5-L chamber was 20.4 and 25.8%, respectively. The functional relationship between actual fat mass of 40 pigeons and fat mass estimated using the most accurate measure of chamber volume is shown in Figure 3. The absolute percent error of the body-fat estimate was not significantly correlated with quantity of body fat (r^ sub2^ = 0.011).

The cyclopropane method is neither userfriendly nor free of unplanned events. We encountered several experimental "problems" that potentially could have introduced significant error in our data set (Table 3). We evaluated these problems by removing the data that were collected on 16 pigeons when one or more experimental problems occurred. Elimination of these problem samples reduced the overall error from 11.8% to 10.5% in the 3.5-L chambers (n = 19) and increased the error from 9.4% to 10.9% in the 4.5-L chamber (n = 5; Fig. 2). Thus, these experimental problems did not contribute significantly to the overall error of the FM estimated for 40 pigeons.

DISCUSSION

The chamber volume that provided the most accurate estimate of FM when using the 3.5-L and 4.5-L chambers was 1.90 and 3.85% lower, respectively, than the water volume. Henen (1991) used water volume of his chamber to compute FM. Lesser et al. (1952) did not specify the method used to measure chamber volume, but stated (p. 550) that "corrections are made throughout for temperature, pressure and water vapor existing in the burette, chamber and lungs of the animal." We corrected for temperature and pressure in all gas samples, but not for vapor pressure, because we did not measure vapor pressure. The vapor pressure of our injected cyclopropane undoubtedly was zero. In contrast, the vapor pressure in the chamber at final equilibrium could have reached saturation levels (30 mm) at the mean chamber temperature of 28.7C. This undoubtedly was the case in 11 measurements where condensation accumulated on the inside chamber walls. Our findings imply that either the vapor pressure in the chamber should be measured and corrected for, or it should be minimized by using a lot more water absorbent than we used.

Repeated measurements of the cyclopropane dilution volume of the 3.5-L chambers (A and C) and the 4.5-L chamber (D) clearly show the level of imprecision in our analytical procedures (Table 2). Standard deviations associated with measurement of the mean dilution volumes of chambers A, C, and D were 4.2, 3.5, and 2.5 % of the means, respectively. Apparently, the mean inaccuracy of the cyclopropane absorption method for estimating avian FM is due, in large part, to the analytical procedures and equipment, rather than to the bird. The cyclopropane method of estimating fat may improve with better accuracy of injecting, sampling, and analyzing for cyclopropane. Lesser et al. (1952), who reported a mean error of 5% for the FM of rats, measured cyclopropane with a titrimetric method, whereas cyclopropane was measured with a gas chromatograph in our study and that of Henen (1991); both studies found an error of about 10%. These reported differences in accuracy may reflect differences in the accuracy of the analytical equipment.

The 10% error in the cyclopropane method reported by Henen (1991) is similar to our findings. We used petroleum ether, whereas Henen used a 2:1 (volume/volume) chloroform-methanol solution to extract the fat from pond turtles. Dobush et al. (1985:1919) showed that a chloroform-methanol mixture removes total lipid and a substantial amount of nonlipid contaminants, and "because of the amount of nonlipid material removed by chloroform-methanol, caution is advised in interpreting the conclusions of these studies." In contrast, Lesser et al. (1952) used ethyl ether to extract the fat of rats, which Dobush et al. (1985) recommended as an appropriate extractor solvent, along with petroleum ether, in studies of body composition in animals. They also measured the solubility coefficient of cyclopropane in fat on pooled samples of rat fat that had been extracted with ethyl ether; thus, these coefficients are for nonpolar fats.

SENSITIVITY ANALYSIS

By using a sensitivity analysis of the variables in the equations used to compute body fat from cyclopropane absorption data, Henen (1991) showed that the fat estimate is most sensitive to small errors in 8 of 15 variables. He reported the following percentage overestimates (positive values) and underestimates (negative values) of fat due to an overestimate of 1% in these eight variables: (1) chamber pressure,-4.3%; (2) mole fraction of cyclopropane in chamber at equilibrium, -4.3%; (3) pressure of cyclopropane in the injection syringe, 4.3%; (4) volume of cyclopropane in the injection syringe, 4.3%; (5) effective volume of the chamber, -2.9%; (6) animal volume, 1.2%; (7) solubility coefficient of cyclopropane in fat, -1.0%; and (8) body temperature, 0.89%.

In the following discussion, we assess the accuracy of our measurements of these eight variables, which includes a sensitivity analysis of our data in an attempt to reveal potential errors in our measurements of five of these eight variables. Also, we assess the effect of estimating rather than measuring body water on the accuracy of predicting FM. In the sensitivity analyses, we incremented only one variable at a time around its measured value, and we always used the chamber volumes that resulted in mean minimum absolute error as shown in Figure 2. We concluded that the measured value of the variable was accurate if the mean absolute error was not significantly improved by using values above or below the value measured in the computations.

Chamber pressure.-We believe that chamber pressure, which was maintained at atmospheric pressure (measured with a mercury barometer) by injecting air or oxygen into the chamber, was measured accurately.

Mole fraction of cyclopropane in chamber at equilibrium.-The accuracy of the measurement of this variable depends on the performance of the gas chromatograph and on the accuracy of measuring the volumes of the glass flasks and syringe used to prepare the standard gas mixtures; we calibrated all three volumes with water (the water mass-to-volume conversion was corrected for temperature). Using repeated measurements of cyclopropane dilution to measure chamber volume, the computed volumes for chambers A, C, and D were 3.554 L (SD = 0.149), 3.638 L (SD = 0.129) and 4.642 L (SD = 0.114), respectively (Table 2). The unexpectedly high standard deviation for each chamber suggests that our system for measuring the mole fraction of cyclopropane in the chamber or for measuring the volume of cyclopropane injected into the chamber was somewhat imprecise. A sensitivity analysis of mole fractions of cyclopropane on the error of the fat estimate shows that minimum error occurred within

Pressure and volume of cyclopropane in the injection syringe.-We believe that the pressure of cyclopropane in the injection syringe, which was purged to atmospheric pressure before injection, was measured accurately. Although the 50-mL syringe was calibrated with water, small consistent errors (certainly not exceeding 1 mL [2% of volume]) could occur. In the sensitivity analysis, a +/- 2% error in injection volume increases the absolute error from 11.8 to 22.7% in the 3.5-L chambers and from 9.4 to 15.0% in the 4.5-L chamber (Fig. 4B). Because the mean minimum absolute error occurred within

Effective volume of the chamber and animal.These two volumes are co-dependent; therefore, any error in animal volume results in an error in effective volume, making it more difficult to separate the potential contribution of each of these volumes to error in our data set. We measured the volume of a frozen pigeon as the difference between the cyclopropane dilution volume of the chamber when empty and when containing a frozen pigeon. Cyclopropane, undoubtedly, did not enter the lungs, air sacs, and gut lumen of the frozen carcass as it would have in a live pigeon; thus, we did not measure these combined volumes of space in the live pigeon, which should be considered as part of the chamber and effective volumes.

Henen (1991) measured a mean density for five turtles of 1.17 by weighing volumes of homogenized carcasses in graduated cylinders; thus, his volumes excluded the volume of air in the respiratory tract. Therefore, the density of our frozen pigeon (1.1 kg/L, n = 1), which we used to compute the volume of our live pigeons, could be more than that of a live pigeon. The density of a pigeon should be within the range of 0.9 to 1.2, because fat density is 0.9, lean tissue density is about 1.1, and the volumes of the respiratory and gastrointestinal tracts would reduce the density below that of a solid mass of mixed fat and lean tissue. A sensitivity analysis using animal densities of 0.9, 1.0, 1.1, and 1.2 to compute pigeon volume from its body mass shows that the minimum error occurred with a density of 1.08 and that error increased only a few percent at densities of 1 and 1.2 (Fig. 5A). Thus, a density of from 1.08 to 1.1 is appropriate for pigeons.

Solubility coefficient of cyclopropane in fat.-Because we lacked equipment to measure the solubility of cyclopropane in pigeon fat, we examined the possibility that the solubility of cyclopropane in the fat of rats might differ significantly from that of pigeons. We used solubilities 5% larger and 5% smaller than rat lipid solubility to recompute an estimate of pigeon fat. For pigeons measured in the 3.5-L chambers and in the 4.5-L chamber, the minimum absolute error occurred using rat lipid solubility (RLS) and 0.97 x RLS, respectively, indicating that the solubility coefficient of cyclopropane in rat fat is appropriate for use with pigeons (Fig. 5B).

Temperature of fat.-Computed fat mass varies inversely with temperature of the fat. Although Lesser et al. (1952) pointed out that an error of 1 to 2 deg C in estimating mean body-fat temperature would result in an error of less than 4% in estimated body fat, we examined this factor as a potential source of error in our data set. We used cloacal temperature in computing the solubility of cyclopropane in body fat, thus assuming that the mean temperature of all body fat (including fat in subcutaneous, abdominal, and intramuscular locations) equaled cloacal temperature. Because the temperature of various parts of the body could be appreciably different (e.g. subcutaneous vs. abdominal), we examined the potential error of using cloacal temperature to represent mean fat temperature. The percent error of fat estimates of pigeons in both the 3.5-L and 4.5-L chambers was lowest when fat temperature used to compute body fat was within loC of the measured cloacal temperature (Fig. 6A).

Body water.-We also examined the sensitivity of our data set to potential errors in the estimate of body water. Although the cyclopropane method is designed to be noninvasive and nonlethal, the calculations require a measure or estimate of the total body water of the animal. Because it is impractical to measure the body water of a bird by isotopic water dilution concomitant with measuring its body fat by cyclopropane absorption, a reasonable estimate of body water must be used. Although the mean percent water content of the lean mass of birds has a narrow range (i.e. 64 to 68.3%; Child and Marshall 1970, Robbins 1993:227, Skagen et al. 1993), the percent water in a bird's body (fat and lean components) varies inversely with percent body fat (see Robbins 1993:figure 11.2). At 5 and 20% body fat, for example, the equation of Robbins (1993:228) predicts body water of 64.6 and 53.8%, respectively. In our sensitivity analysis over the range of 52 to 64% body water, the mean absolute percent error of the fat estimate of birds in both 3.5-L and 4.5-L chambers changed by less than 1% (Fig. 6B). The fat estimate was relatively independent of changes in the proportion of water in the body, because on average 83% of all cyclopropane absorbed into the body of our pigeons was dissolved in fat.

SUGGESTIONS FOR FUTURE USE

The advantages and disadvantages of cyclopropane absorption method are listed in Appendix 2. The error of estimating body fat by the cyclopropane method can be minimized by careful attention to measurement of gas volumes, prevention of gas leaks from the chamber, and preparation of standards used in calibrating the gas chromatograph. We recommend the following steps or procedures to help reduce undesirable gas-volume fluctuations during delivering and withdrawing gas samples from the chamber and to improve chances of success.

First, the volume of cyclopropane required to establish a 1 to 1.5% cyclopropane level in the chamber should be injected in one delivery, rather than in multiple deliveries that increase the opportunities for error. We used a 50-mL gas syringe for injecting 100% cyclopropane into chamber volumes ranging from 3.5 to 4.5 L. The initial percent cyclopropane in the chamber should always be kept below 2% because cyclopropane is flammable and explosive. The explosive range of cyclopropane in air is 2.4 to 10.3%; in oxygen, 2.5 to 60% (Price 1990).

Second, the operator should wear well-insulated gloves while handling the syringes to prevent warming the syringe barrel and the gas within. Third, periodically check the junction between the syringe and the needle for possible leaks, for example, by looking for bubbles emerging from the junction while a volume of air is delivered from the syringe underwater.

Fourth, the bore of the injection syringe needle occasionally becomes partially or completely plugged with a core of rubber withdrawn from the rubber septum on the chamber sampling port or on the gas chromatograph inlet port. We overcame this problem by blocking the opening of the needle with epoxy and using a metal file to form one or two side holes through the wall of the needle about 0.5 to 1 cm distal to the epoxied end. Although these side holes also can become plugged with rubber, plugging occurs much less frequently than with an open-ended needle. A partially clogged syringe needle, which is indicated when the time required to purge the gas sample to atmospheric pressure underwater is significantly longer, causes the pressure within the syringe to increase significantly above normal during delivery of cyclopropane. This may cause abnormal leakage at the needle/syringe junction or between the syringe piston and cylinder.

Fifth, some 20-WL gas syringes that we used to withdraw samples from the chamber apparently developed leakage around the Teflon piston after considerable use, which was detected from the abnormally low values measured on standard samples. Sixth, manometer and thermocouple wire were attached to the adapter in the lid of each chamber with Teflon tape, which was then epoxied in place to prevent leakage.

Seventh, at the end of a 2- to 3-h equilibrium, a chamber that is opened to room air will continue to contain some cyclopropane for more than an hour; therefore, it must be ventilated with a fan for several minutes or completely filled with water and dried to remove all of the cyclopropane before using the chamber in another trial that day. The equations assume that all of the cyclopropane in the chamber at the beginning of a trial comes from injected cyclopropane.

Eighth, we found that pouches of Drierite and soda lime removed from a chamber at the end of equilibrium and placed in another chamber, initially free of cyclopropane, caused a detectable level of cyclopropane in the second chamber. This suggests that cyclopropane had been taken up by water accumulating in absorbents during the equilibrium period and had washed out in the second chamber. Thus, Drierite should be dried in an oven before being reused in subsequent trials.

Ninth, the outer walls of the reaction chamber should be cooled (e.g. with a jacket of circulating water) to maintain the chamber temperature near the lower end of the thermoneutral zone of the species. Five of 16 larger pigeons weighing >=397 g died of hyperthermia (final T^ subB^ = 44.6 +/- 1.2 degC, mean M^ subB^ = 432.6+/- 32.9 g). The other 11 larger pigeons had a final T^ subB^ of 43.0 +/- 1.8 degC. None of the 27 pigeons

Finally, to minimize error, the standard gases used to calibrate the gas chromatograph should be prepared in glass flasks having a volume 20 to 100% of the animal chamber volume. For example, we used 1-L volumetric flasks to prepare the standard gas samples; our chamber volumes ranged from 3.5 to 4.5 L. In preliminary work to calibrate our system using olive oil, we found that the preparation of standards in volumes about 1% of our chamber volumes caused spurious results.

We believe that the precision and accuracy of a system assembled for use with the cyclopropane method should be evaluated before using it on animals. Precision can be evaluated from repeated measurements of chamber volume by cyclopropane dilution, and accuracy (and precision) can be evaluated with olive oil, as a substitute for animal fat, in the chamber.

Although a mean error of 11% in estimating avian body fat is impressively small when compared with the error reported by some users of the total body electrical conductivity method (e.g. 23.2% error, Skagen et al. 1993; 362% error, Morton et al. 1991) we recommend that potential users of this method carefully consider the limitations of an 11% error in estimating body fat before attempting to use this moderately difficult method. A convenient way to assess the magnitude of the energy equivalent of this error is to compare it with basal metabolic rate or with daily energy expenditure (DEE) predicted from allometric equations. For example, what fraction of the DEE does a 11% error in fat represent for the bird's under study? The error is equivalent to 1 to 2 times DEE for birds that weigh from 100 to 1,000 g and have 5% body fat, and it represents larger multiples of DEE for larger and fatter birds. For example, the error is about 12 times DEE for a 1,000-g bird with 25% body fat (Fig. 7). Will this kind of error allow you to measure anticipated changes in the body fat of your study species with the accuracy needed to test your hypotheses or to clearly discriminate significant changes in body fat associated with seasonal events or life cycle stages? If the answers to these questions are not clearly affirmative, we do not recommend the use of this user-unfriendly method.

ACKNOWLEDGMENTS

We thank Sheldon Cooper and James Haefner for reviewing earlier versions of this paper. Funding was provided by Financial Assistance Award Number DE-FC09-96SR18546 from the United States Department of Energy to the University of Georgia Research Foundation.

LITERATURE CITED

BLEM, C. R. 1990. Avian energy storage. Current Ornithology 7:59-113.

BLUMBERG, A. G., B. N. LA DU, JR., G. T. LESSER, AND J. M. STEELE. 1952. The determination of the solubility of cyclopropane in fats and oils with the use of the Warburg apparatus. Journal of Pharmacology and Experimental Therapeutics 104: 325-328.

CHEMICAL RUBBER COMPANY. 1982. Handbook of chemistry and physics, 63rd ed. CRC Press, Cleveland, Ohio.

CHEREL, Y., J. P. ROBIN, AND Y. LE MAHO. 1987. Physiology and biochemistry of long-term fasting in birds. Canadian Journal of Zoology 66:159-166.

CHILD, G. I., AND S. G. MARSHALL. 1970. A method of estimating carcass fat and fat-free weights in migrant birds from water content of specimens. Condor 72:116-119.

DOBUSH, G. R., C. D. ANKNEY, AND D. G. KREMENTZ. 1985. The effect of apparatus, extraction time, and solvent type on lipid extractions of Snow Geese. Canadian Journal of Zoology 63:19171920.

ELKINS, N. 1993. Weather and bird behaviour. T. and A. D. Poyser, Calton, United Kingdom.

GESSAMAN, J. A., AND G. L. WORTHEN. 1982. The effect of weather on avian mortality. Utah State University Printing Services, Logan. (Available from first author).

HENEN, B. T. 1991. Measuring the lipid content of live animals using cyclopropane gas. American Journal of Physiology 261:R752-R759.

KREMENTZ, D. G., AND G. W. PENDLETON. 1990. Fat scoring: Sources of variability. Condor 92:500507.

LESSER, G. T., A. G. BLUMBERG, AND J. M. STEELE. 1952. Measurement of total body fat in living rats by absorption of cyclopropane. American Journal of Physiology 169:545-553.

MORTON, J. M., R. L. KIRKPATRICK, AND E. P. SMITH. 1991. Comments on estimating total body lipids from measures of lean mass. Condor 93:463465.

NAGY, K. A. 1989. Doubly-labeled water studies of vertebrate physiological ecology. Pages 270-287 in Stable isotopes in ecological research (P. W Rundel, J. R. Ehleringer, and K. A. Nagy, Eds.). Springer-Verlag, New York.

POND, C.M. 1981. Storage. Pages 190-219 in Physiological ecology: An evolutionary approach to resource use (C. R. Townsend and P. Calow, Eds.). Sinauer, Sunderland, Massachusetts.

PRICE, H. L. 1990. General anesthetics-gaseous anesthetics: Nitrous oxide, ethylene and cyclopropane. Pages 81-88 in The pharmacological basis of therapeutics, 5th ed. (L. S. Goodman and A. Gilman, Eds.). Pergamon Press, New York.

ROBBINS, C. T. 1993. Wildlife feeding and nutrition, 2nd ed. Academic Press, New York.

ROGERS, C. M. 1991. An evaluation of the method of estimating body fat in birds by quantifying visible subcutaneous fat. Journal of Field Ornithology 62:349-356.

SKAGEN, S .K., F L. KNOPF, AND B. S. CADE. 1993. Estimation of lipids and lean mass of migrating sandpipers. Condor 95:944-956.

Associate Editor: M. E. Murphy

1Department of Biology and Ecology Center, Utah State University, Logan, Utah 84322, USA; and

2Savannah River Ecology Laboratory, Drawer E, Aiken, South Carolina 29802, USA

3 E-mail: fajimg@cc.usu.edu

Copyright American Ornithologists' Union Jan 1998

Provided by ProQuest Information and Learning Company. All rights Reserved