Combination medical products are hot and becoming hotter. In January, the Food and Drug Administration made headlines by quickly approving a fixed-dose-combination (FDC) treatment for AIDS under a new policy that allows its use in developing nations. Pharmaceutical manufacturers also are building commercial markets at home by developing FDCs offering clinical benefits and/or reduced risk while also improving patient compliance and extending the life cycle of established therapies.

A related FDA initiative clarifies regulatory policies for products that combine drugs, biologics, and medical devices and thus are regulated by multiple agency centers. FDA's Office of Combination Products (OCP) is crafting rules and guidances to govern which FDA center will lead the regulation of new combinations and what manufacturing and compliance policies will apply. The process involves clarifying manufacturing standards, postapproval changes, user-fee requirements, and a host of other issues.

FDA is encouraging innovative product development by modifying preclinical and clinical testing requirements and clarifying manufacturing standards for new combinations. Pharma companies regard combination drugs as a way to address multiple health needs and to simplify treatment regimens, but combination products often require innovative approaches to formulation, manufacturing, and packaging. Health plans and insurers appear receptive to paying a premium for products that offer less risk and more convenience, but manufacturers have to document long-term benefits in terms of savings and enhanced health to gain payor acceptance.

Single pill popularity

Recent FDA approval of several high-profile combination drugs is drawing increased attention to opportunities in this area. Last year, Pfizer introduced Caduet, a drug combining Norvasc (amlodipine besylate) for high blood pressure and Lipitor (atrovastatin calcium) for high cholesterol. Extensive previous patient use of the drugs separately and in combination with no ill effects permitted use of existing preclinical studies to support the combination product's regulatory filing.

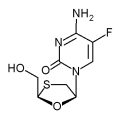

AIDS combination therapies have gained the most notice. In August 2004, FDA approved two combination antiretrovirals for use in the United States as well as in the developing world. The manufacturers had begun testing these products before FDA published a draft guidance in May that not only describes a streamlined process for developing and gaining agency approval of combination AIDS drugs intended only for third-world distribution, but also describes manufacturing approaches that apply to all combination products (see sidebar, "FDA approves AIDS combination drug for overseas use."). GlaxoSmithKline's Epzicom combines 600 mg of Ziagen (abacavir) and 300 mg of Epivir (lamivudine). Because the two component drugs were already on the market, FDA approval was based on a well-controlled clinical study showing that using abacavir only once a day, when taken with lamivudine and another antiretroviral, had a similar antiretroviral effect as its previous twice-daily dosage.

FDA also approved Gilead Sciences' MDS treatment Truvada after only a four-month review. The product combines 300 mg of Viread (tenofovir) and 200 mg of Emtriva (emtricitabine) into a once-daily dose. Speedy development of a stable formulation and a robust product process was facilitated by the fact that both individual products used a common wet granulation process, reported Reza Oliyai of Gilead at a January 2005 conference about "The Single Pill Solution" sponsored by Pharmaceutical Education Associates. Gilead had to conduct bioequivalence studies to demonstrate therapeutic equivalence between the combination drug and the individual products but benefited from reduced clinical testing requirements. Building on this effort, in December Gilead and Bristol-Myers Squibb announced plans to develop an a fixed-dose combination drug of Truvada and BMS' Sustiva (efavirenz) to create a more potent once-daily AIDS treatment.

New life for innovator products

Although FDCs are particularly suitable for providing less costly and simpler treatment regimens for AIDS, malaria, and other diseases plaguing the third world, manufacturers are enthusiastic about moving in this direction in the United States and other established markets as part of product life cycle management. A successful drug facing patent expiration may gain new life through transformation into a combination product. The new formulation may enhance patient compliance not just through simplified treatment regimens but also by reducing toxicity and side effects or boosting drug bioavailability and increasing efficacy. Manufacturers are looking particularly at treatments for asthma, diabetes, hypertension, and infectious diseases as prime opportunities for developing more-effective combination products.

Combination drug products have been around for decades but until recently were saddled with a negative image in the medical community. In the past, physicians objected to combination pills for limiting their ability to prescribe specific doses and therapeutic combinations to fit individual patients. With drugs now playing a much greater role in patient care, and drug costs and safety issues high in the public eye, physicians are beginning to accept FDCs as products that may offer advantages in terms of compliance and reduced safety concerns. Combination products may curb prescribing errors by physicians and dispensing mistakes by pharmacists and healthcare professionals. Distribution and storage also may be easier with one product.

The dominance of managed care in today's healthcare system, moreover, is making physicians more receptive to practice standards for treating certain conditions; if a combination medicine gains acceptance as a preferred treatment for a specific disease or condition, then the medical community is more likely to accept that approach.

On the down side, the shift to combination products may reduce the range of treatment options available to physicians and patients. In developing a combination product, manufacturers often drop less-used dosage strengths and produce a more limited range of treatments, reducing prescribing choices.

Manufacturing challenges

The main obstacle to FDC development usually involves product formulation and manufacturing issues. The process has to ensure that the mixing of separate active ingredients does not raise new drug-drug interaction issues or compromise product stability or dissolution rates. All active ingredients and excipients of the two products must be compatible; solubility could be affected by combining ingredients with different pH levels, which could alter absorption rates. New combinations also could lead to product discoloration. The combined product's degradation rate must be tested to ensure that the product ~11 remain stable during a practical shelf life.

Innovative combination formulations also require new analytical procedures to accurately assess product strength, uniformity, quality, and purity. When one substance in a product has a lower or higher concentration than the other, testing may be difficult. More important, in most cases manufacturers must demonstrate that in vivo interactions between active ingredients and excipients do not alter a product's pharmacokinetic profile.

When formulating a single pill from incompatible ingredients is too difficult, a manufacturer may opt to offer a combination product as individual dosage forms combined in composite packaging. The disadvantage of this approach is that the patient has to take more than one pill, increasing the possibility of error or faulty compliance. And the manufacturer has to revise packaging systems and product labeling. Some reformulation may be needed to ensure that all component medicines have similar dosing regimens and food effects; a company would not normally co-package a once-a-day pill with one that has to be taken more often.

Because a single combination pill offers considerable advantages, manufacturers are developing new methods to prevent undesirable effects from mixing incompatible ingredients:

* Layered tablets. Similar to manufacturing processes for some multivitamin tablets, manufacturers are developing double- and triple-layer tablets to minimize physical contact between active ingredients, similar to what occurs when adding aspirin to other active ingredients.

* Segregation techniques. Manufacturers are exploring new ways to coat particles of incompatible substances.

* Multicompartment capsules. These permit the combination of an insoluble active and a sustained-release tablet, among other combinations, but may raise stability problems.

Less testing

To encourage combination drug development, FDA is developing policies to clarify and in some cases streamline testing requirements. A new draft guidance from FDA proposes less-extensive preclinical safety testing for certain new FDCs and copackaged versions of already approved drugs, and even combinations of an approved and a new drug (www.fda.gov/ cder/guidance/5629dft.pdf). If existing toxicological and pharmacokinetic information shows no evidence to suggest possible harmful interaction of the combined drugs, FDA may allow the manufacturer to begin Phase I clinical studies without first conducting extensive animal tests. Bridging studies may suffice for new-old combinations, particularly if it is believed the safety profile of the old drug would not change. FDA urges manufacturers to consult with the appropriate drug review division about any specific testing protocol, but the agency guidance aims to establish more uniform standards for reduced preclinical testing across all of FDA's new-drug review divisions.

Broader combos

FDA also is clarifying its policies for overseeing and bringing to market a growing number of products made of separate components such as drugs and medical devices, which normally are regulated by separate FDA centers under different regulations. Medical device legislation enacted in 2002 called for FDA to establish a central office to oversee assignment of such combination products to the appropriate center to ensure speedy review. The agency responded by establishing the Office of Combination Products (OCP) in late 2002 to deal with the testing and regulatory issues raised by an increasing number of advanced diagnostics and drug delivery devices under development. In May 2004, FDA issued a proposed regulation to govern how OCP will determine a product's "primary mode of action" and consequently which FDA center will have primary jurisdiction over the product. Manufacturers have urged FDA to consider previous agency decisions about jurisdictional assignments in finalizing the rule, already raising questions about how combinations are regulated.

Another OCP draft guidance describes procedures for a manufacturer to dispute a product assignment decision and clarifies how the agency will levy user fees for combination products. OCP offers to assist manufacturers who believe that an FDA center is moving too slowly in reviewing a market application, acknowledging that problems and delays are more likely when more than one center is involved with a more complex registration process. The guidance also explains that user fees will follow the lead center, but that the manufacturer may have to pay two fees if it files two separate applications, a situation that the agency anticipates will not occur often. OCP is planning to issue further guidance about how manufacturers should determine the appropriate number of premarket applications for combination products.

In September, FDA also issued a draft guidance governing good manufacturing practices for combination products. The document aims to clarify which rules and standards apply to products that combine drugs or biologics (which follow GMPs) with a medical device (which are governed by quality system regulations). Manufacturers generally have to follow all applicable product quality standards but are encouraged to consult OCP when embarking on the development of a combination product to ensure that they follow all appropriate testing and control requirements.

OCP plans to issue further guidances on how manufacturers should report adverse events and handle post-marketing manufacturing changes. Another thorny issue involves cross-labeling for combinations designed to be used together but are manufactured separately. OCP is seeking public comment on this topic and plans to hold a public meeting this spring to examine it further.

Despite FDA's efforts to establish a dearer and more predictable path for developing and regulating combination products, manufacturers still feel that FDA centers for drugs, devices, and biologics follow very different regulatory processes and often take diverse approaches to application review. These concerns were discussed at a January 2005 summit about combination products sponsored by the Regulatory Affairs Professionals Society, which ended up urging FDA to develop a more consistent approach to reviewing combination products. An initial proposal is for FDA to develop a common set of terms and definitions, starting with the term combination product. Manufacturers are weighing whether FDA should seek a separate user fee for combination products to avoid double billing and how best to deal with supplements related to manufacturing changes.

To date, most combination products and fixed-dose combination pills involve already-approved components that a company combines into a new therapy. With a large number of suitable combinations already on the market, manufacturers will be looking more to combine new therapies into new types of combination products. These may be costly for manufacturers to develop but provide simplified dosing regimens and improved safety that may pay off in stronger market acceptance.

FDA approves AIDS combination drug for overseas use.

In January, FDA approved a copackaged antiretroviral drug regimen, manufactured by Aspen Pharmacare of South Africa, under a new policy that qualifies certain AIDS treatments for distribution in developing nations, even though the components are patented in the United States. The new product includes generic versions of GlaxoSmithKline's Combivir (lamivudine/zidovudine fixed dose combination tablet) copackaged with Boehringer-Ingelheim's Viramune (nevirapine). Both innovator firms granted Aspen permission to produce versions of their patented products for use in Africa.

Under FDA's rolling review procedure, Aspen gained final tentative approval only two weeks after FDA received the last data piece (the tentative designation remains in place until innovator patents expire in 2018). FDA also waived the usual $500,000 application fee.

The regulatory process involved a 505 (b) (2) submission that was approved by the Division of Antiviral Drug Products, as opposed to the Office of Generic Drugs. (The Aspen product technically is not a generic drug because no previously approved version of this copackaged treatment exists). The normal requirements for clinical data were waived because the innovator firms allowed Aspen to cross-reference their safety and efficacy studies. Aspen did have to conduct bioequivalence studies and to submit stability data. FDA also requires Aspen to establish a system for collecting and reporting adverse drug reactions from product distributors.

FDA spelled out its requirements for accelerated approval of fixed-dose combinations (FDCs) in a May 2004 draft guidance. FDA regulations normally require manufacturers developing FDCs to conduct clinical trials to demonstrate that the combination product is more effective than each component used separately. In treating AIDS, though, FDA acknowledges that such clinical trials are unethical because they would involve exposing infected individuals to suboptimal drug regimens. Manufacturers of new combination products of approved AIDS therapies thus may only have to submit data from bioavailability, bioequivalence, and drug-drug interaction studies to ensure appropriate interaction of the components. Manufacturers also must demonstrate appropriate manufacturing process controls and stability of the combination product.

Jill Wechsler is Pharmaceutical Technology's Washington editor, 7715 Rocton Ave., Chevy Chase, MD 20815, tel. 301.656.4634, jwechsler@advanstar.com.

COPYRIGHT 2005 Advanstar Communications, Inc.

COPYRIGHT 2005 Gale Group