METHOD OF PREPARATION

Note: This formulation should be prepared in a laminar airflow hood in a cleanroom or via isolation barrier technology by a validated aseptic compounding pharmacist using strict aseptic technique. This is a high-risk preparation.1

1. Calculate the required quantity of each ingredient for the total amount to be prepared.

2. Accurately weigh and/or measure each ingredient.

3. Dissolve the morphine sulfate, atropine sulfate, and sodium chloride in about 95 mL of sterile water for injection.

4. Add sufficient sterile water for injection to volume and mix well.

5. Filter through an appropriate sterile 0.22-pm filter into a suitable sterile, single-use container (vial, syringe).

6. Package and label.

PACKAGING

Package in sterile containers.1

LABELING

Keep out of reach of children. Use only as directed. For professional use only.

STABILITY

If not sterility tested: A beyond-use date of up to 24 hours at room temperature, up to 3 days at refrigerated temperature (2° to 8° C), or up to 45 days if frozen can be used for this preparation.

If sterility tested: A beyond-use date of up to 14 days stored in a refrigerator can be used for this preparation.1

USE

Morphine sulfate with atropine sulfate injection is used in the treatment of severe pain.

QUALITY CONTROL

Quality-control assessment can include weight/volume, physical observation, pH, specific gravity, osmolality, assay, color, clarity, particulate matter, sterility, and pyrogenicity.2,3

The endotoxin unit (EU) maximum would be 27,200 for 1,600 mg of morphine sulfate. The EU maximum would be 2,224 for 40 mg of atropine sulfate. For 812 mg of sodium chloride, the EU maximum would be 0.5 units per milliliter; if 100 mL is used, this would be 50 EU, based on sodium chloride injection. The total maximum endotoxin level would be 27,200 + 2,224 + 50 = 29,474 EU for the 100 mL or 294.74 EU per milliliter.

DISCUSSION

Morphine sulfate with atropine sulfate injection was formerly available from SmithKline Beecham but was discontinued in 2002.

Morphine sulfate [(C^sub 17^H^sub 19^NO^sub 3^)^sub 2^.H^sub 2^SO^sub 4^.^sub 5^H^sub 2^O, MW 758.83] occurs as white, feathery, silky crystals, cubical masses of crystals, or white, crystalline powder. It is odorless and when exposed to air it gradually loses water of hydration. It darkens on prolonged exposure to light and should be stored in a tight, light-resistant container. It is soluble in water and freely soluble in hot water. It is slightly soluble in alcohol.1 Morphine Sulfate Injection USP is a sterile solution of Morphine Sulfate in Water for Injection. It contains not less than 90.0% and not more than 110.0% of the labeled amount of morphine sulfate pentahydrate. Injection intended for intramuscular or intravenous administration may contain sodium chloride as a tonicity-adjusting agent, and suitable antioxidants and antimicrobial agents. Morphine Sulfate Injection USP has a pH between 2.5 and 6.5 and an endotoxin limit of not more than 17.0 EU per milligram of morphine sulfate if intended for other than intrathecal use.1

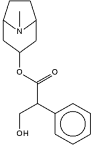

Atropine sulfate [(C^sub 17^H^sub 23^NO^sub 3^)^sub 2^.H^sub 2^SO^sub 4^.H^sub 2^O, MW 694.83] occurs as colorless crystals, or as a white, crystalline powder. It is odorless and effloresces in dry air. It is slowly affected by light. It is very soluble in water and freely soluble in alcohol and glycerin. It should be preserved in tight containers. Atropine sulfate injection contains not more than 55.6 EU per milligram of atropine sulfate.1

Sodium chloride (NaCl, MW 58.44) is available as a white crystalline powder or as colorless crystals. It is soluble in water (1 g in 2.8 mL), glycerin (1 g in 10 mL), and 95% ethanol (1 g in 250 mL). For sodium chloride injection whose concentration of sodium chloride is between 0.5% and 0.90%, the endotoxin limit is not more than 0.5 USP EU per milliliter.4

Sterile water for injection is water for injection that has been sterilized and suitably packaged; it contains no added substance.5

References

1. United States Pharmacopeial Convention, Inc. United States Pharmacopeia 28-National Formulary 23. Rockville, MD: US Pharmacopeial Convention, Inc.; 2004: 200-201, 1315-1316, 2345-2349, 2457-2477, 2878, 2901.

2. Allen LV Jr. Standard operating procedure for particulate testing for sterile products. IJPC 1998; 2(1): 78.

3. Allen LV Jr. Standard operating procedure: Quality assessment for injectable solutions. IJPC 1999; 3(5): 406-407.

4. Owen SC. Sodium chloride. In: Rowe RC, Sheskey PJ, Weller PJ. Handbook of Pharmaceutical Excipients. 4th ed. Washington, DC: American Pharmaceutical Association; 2003: 556-559.

5. Ellison A, Nash RA, Wilkin MJ. Water. In: Rowe RC, Sheskey PJ, Weller PJ, eds. Handbook of Pharmaceutical Excipients. 4th ed. Washington, DC: American Pharmaceutical Association; 2003: 672-676.

Copyright International Journal of Pharmaceutical Compounding Sep/Oct 2005

Provided by ProQuest Information and Learning Company. All rights Reserved